Forged globe valves play a crucial role in regulating the flow of fluids in various industrial applications, from oil and gas to chemical processing plants. Their robust construction and reliable performance make them indispensable components in pipelines and systems where precise control is necessary. In this comprehensive guide, we delve into the intricate details of the construction and working principle of forged globe valves, shedding light on their functionality and importance in engineering systems.

Construction of Forged Globe Valves:

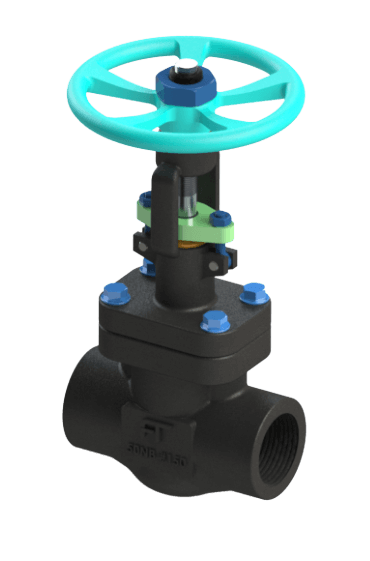

Forged globe valves are meticulously engineered to withstand high pressures and temperatures while ensuring smooth operation and minimal leakage. The construction of these valves comprises several key components, each playing a vital role in their functionality:

Body: The body of a forged globe valve is typically made of forged steel, which is known for its strength and durability. The body houses the internal components of the valve and provides a robust enclosure to withstand the forces exerted by fluid pressure.

Bonnet: The bonnet is attached to the top of the valve body and serves as a cover to protect the internal components. It also provides a seal to prevent leakage from the valve stem.

Disc: The disc, also known as the plug or the disk, is the movable component that controls the flow of fluid through the valve. In a forged globe valve, the disc is attached to the valve stem and moves perpendicular to the flow direction to open or close the valve.

Seat: The seat forms a tight seal around the disc to prevent leakage when the valve is closed. It is typically made of materials such as stainless steel or hardened alloy to withstand wear and corrosion.

Stem: The stem connects the handwheel or actuator to the disc and transmits the operator's input to control the flow of fluid. It must be robust enough to withstand the forces exerted during operation while maintaining proper alignment with the disc.

|

| High Pressure API 602/623 Forged Steel Globe Valves |

Working Principle of Forged Globe Valves:

The working principle of forged globe valves is based on the movement of the disc relative to the seat to control the flow of fluid. When the valve is in the closed position, the disc is pressed against the seat, forming a tight seal that prevents the passage of fluid. As the handwheel or actuator is turned to open the valve, the stem moves upward, lifting the disc away from the seat and allowing fluid to flow through the valve.

One of the distinguishing features of globe valves is their linear motion stem design, which provides precise control over the position of the disc. This design enables fine adjustments to the flow rate, making globe valves ideal for applications where accurate flow regulation is essential.

The flow characteristics of forged globe valves are generally characterized as "linear" or "equal percentage," depending on the shape of the disc and seat. In linear flow valves, the relationship between the valve opening and flow rate is proportional, resulting in a consistent change in flow for a given change in valve position. In contrast, equal percentage flow valves exhibit a non-linear relationship, where small changes in valve position result in larger changes in flow rate, making them suitable for applications requiring fine flow control.

Applications of Forged Globe Valves:

Forged globe valves find widespread use in industries where precise flow control is critical, including:

Oil and Gas: Forged globe valves are commonly used in upstream, midstream, and downstream operations to regulate the flow of crude oil, natural gas, and refined products.

Petrochemicals: These valves play a vital role in petrochemical plants for controlling the flow of various chemicals and fluids in refining and processing operations.

Power Generation: In power plants, forged globe valves are employed in steam, water, and gas systems to control the flow of fluids in boilers, turbines, and other equipment.

Chemical Processing: Forged globe valves are utilized in chemical processing plants to regulate the flow of corrosive and abrasive fluids in reactors, distillation columns, and storage tanks.

Marine and Shipbuilding: Globe valves are essential components in marine applications, including shipboard systems for controlling seawater, fuel, and hydraulic fluids.

Conclusion:

Forged Steel Globe valves are indispensable components in engineering systems where precise flow control is essential. Their robust construction, reliable performance, and versatile applications make them a preferred choice in various industries, including oil and gas, petrochemicals, power generation, and chemical processing. By understanding the construction and working principle of forged globe valves, engineers and operators can effectively utilize these valves to optimize system performance and ensure safe and efficient operation.

No comments:

Post a Comment