Forged globe valves play a vital role in numerous industrial applications, regulating the flow of liquids and gases with precision and reliability. However, like any mechanical component, they are subject to wear, tear, and operational challenges over time. In this article, we delve into the common issues encountered in maintaining forged globe valves and explore effective solutions to ensure their continued efficiency and longevity.

Understanding Forged Steel Globe Valves:

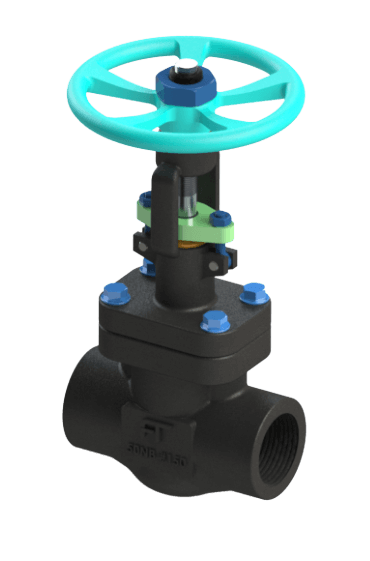

Before delving into maintenance challenges, it's essential to grasp the fundamentals of forged globe valves. These valves are distinguished by their globe-shaped body and a movable disk (or plug) that regulates flow through the valve. They are commonly used in applications requiring precise flow control, such as oil and gas, petrochemical, and power generation industries.

|

| Forged Steel Globe Valve for High Pressure Application |

Common Maintenance Challenges:

Leakage: One of the most prevalent issues faced with forged globe valves is leakage. This can occur due to worn-out sealing components, corrosion, or improper installation. Even a minor leak can result in significant energy loss and compromise system efficiency.

Corrosion and Erosion: In harsh operating environments, forged globe valves are susceptible to corrosion and erosion, especially when handling corrosive fluids or abrasive particles. Corrosion can weaken valve components, leading to leaks and operational failures if left unchecked.

Stem Packing Wear: The stem packing of globe valves is crucial for maintaining a tight seal and preventing leakage. However, continuous operation can cause wear and deterioration of the packing material, resulting in leakage around the stem.

Sticking or Binding: Over time, forged globe valves may experience sticking or binding of the valve disk due to accumulation of debris, corrosion, or inadequate lubrication. This can impede the smooth operation of the valve, affecting flow control and system performance.

Actuator Malfunction: Forged globe valves equipped with actuators for automated operation may face issues such as motor failure, electrical faults, or control system malfunctions. These problems can disrupt the intended operation of the valve and require prompt attention to restore functionality.

Effective Maintenance Solutions:

Regular Inspection and Maintenance: Implementing a proactive maintenance schedule is essential for detecting and addressing potential issues before they escalate. Regular inspections should include checking for leaks, corrosion, and proper functioning of all valve components.

Corrosion Protection: Employing corrosion-resistant materials or protective coatings can help mitigate the effects of corrosive environments on forged globe valves. Additionally, installing sacrificial anodes or cathodic protection systems can further safeguard against corrosion.

Stem Packing Replacement: Periodic replacement of stem packing is necessary to maintain the integrity of the valve seal. Using high-quality packing materials and following manufacturer recommendations for packing installation and adjustment can prolong the lifespan of the valve packing.

Cleaning and Lubrication: Routine cleaning of valve internals and proper lubrication of moving parts can prevent sticking or binding issues. Utilizing compatible lubricants and following lubrication schedules specified by the manufacturer are essential for optimal valve performance.

Actuator Maintenance: For valves equipped with actuators, regular inspection and testing of the actuator components are crucial. This includes checking motor operation, calibration of control systems, and ensuring proper alignment with valve position indicators.

Maintaining forged globe valves is essential for ensuring uninterrupted operation and maximizing system efficiency. By addressing common maintenance challenges proactively and implementing effective solutions, industries can prolong the lifespan of their valves and minimize costly downtime. With proper care and attention, forged globe valves will continue to serve as reliable components in critical industrial processes

No comments:

Post a Comment