In the intricate web of industrial machinery, every component plays a crucial role in ensuring seamless operations. Among these components, forged globe valves stand out as essential elements for controlling the flow of fluids in various applications. However, selecting the right forged globe valve for your specific needs requires careful consideration and understanding. In this comprehensive guide, we will delve into the key factors to consider when choosing a forged globe valve for your application, ensuring optimal performance and efficiency.

Understanding Forged Steel Globe Valves:

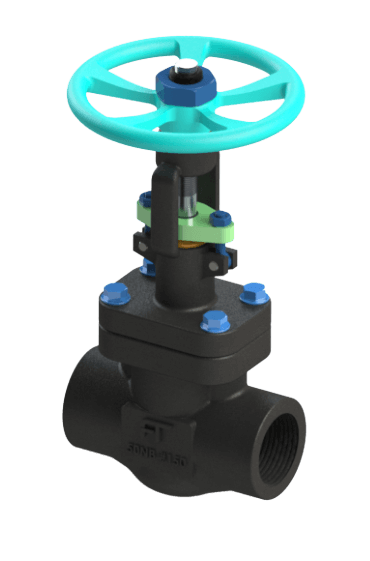

Before diving into the selection process, let's first understand what forged globe valves are and how they function. Forged globe valves are vital components in piping systems, designed to regulate fluid flow by opening, closing, or partially obstructing the passage. Unlike their cast counterparts, forged globe valves are manufactured by shaping heated metal under high pressure, resulting in a more robust and durable construction.

|

| Forged Steel Globe Valve price |

Key Factors to Consider:

Operating Conditions:

The first step in selecting the right forged globe valve is to evaluate the operating conditions of your application. Consider factors such as temperature, pressure, and the nature of the fluid being transported. For high-pressure or high-temperature environments, opt for forged globe valves with reinforced construction and suitable materials to withstand the demanding conditions.

Material Selection:

The choice of materials plays a crucial role in the performance and longevity of forged globe valves. Common materials include carbon steel, stainless steel, and alloy steel, each offering unique properties suited for specific applications. Carbon steel valves are ideal for general-purpose applications, while stainless steel provides excellent corrosion resistance, making it suitable for corrosive environments. Alloy steel valves offer enhanced strength and durability, making them ideal for high-pressure applications.

Valve Size and Flow Capacity:

Selecting the right valve size is essential to ensure efficient fluid flow within your system. Consider factors such as pipe diameter, flow rate, and pressure drop when determining the appropriate valve size. Consult industry standards and guidelines to determine the required flow capacity for your application and select a forged globe valve that meets or exceeds these requirements.

Valve Design and Configuration:

Forged globe valves are available in various designs and configurations to suit different applications. Common designs include angle, Y-pattern, and straight pattern valves, each offering specific advantages depending on the installation requirements. Evaluate factors such as space limitations, piping layout, and accessibility when choosing the appropriate valve design for your application.

End Connections and Mounting Options:

Consider the end connections and mounting options available for forged globe valves to ensure compatibility with your existing piping system. Common end connection types include threaded, flanged, and welded connections, each offering distinct advantages in terms of installation and maintenance. Choose the appropriate end connections based on your system requirements and installation preferences.

Compliance with Industry Standards:

Ensure that the forged globe valves you select comply with relevant industry standards and specifications to guarantee reliability and performance. Look for certifications such as API, ASME, and ISO, which indicate adherence to quality and safety standards. Compliance with industry standards also ensures interchangeability and compatibility with other components within your system.

Maintenance and Serviceability:

Consider the ease of maintenance and serviceability when selecting forged globe valves for your application. Opt for valves with accessible components and straightforward maintenance procedures to minimize downtime and enhance operational efficiency. Additionally, choose valves from reputable manufacturers known for their quality craftsmanship and reliable customer support.

Conclusion:

Selecting the right forged globe valve for your application requires careful consideration of various factors, including operating conditions, material selection, valve size, design, end connections, compliance with industry standards, and maintenance requirements. By following the guidelines outlined in this comprehensive guide, you can ensure optimal performance, reliability, and longevity of your API 602/623 Forged Steel Globe valves, ultimately contributing to the efficiency and productivity of your industrial operations.

No comments:

Post a Comment