In the intricate machinery of industrial operations, every component plays a vital role in ensuring seamless functionality and optimal performance. Among these components, forged globe valves stand out as indispensable assets, offering a myriad of advantages that contribute to enhanced efficiency and reliability. From their robust construction to their versatile applications, forged globe valves have earned their place as essential elements in a wide range of industrial settings.

Understanding Forged Globe Valves

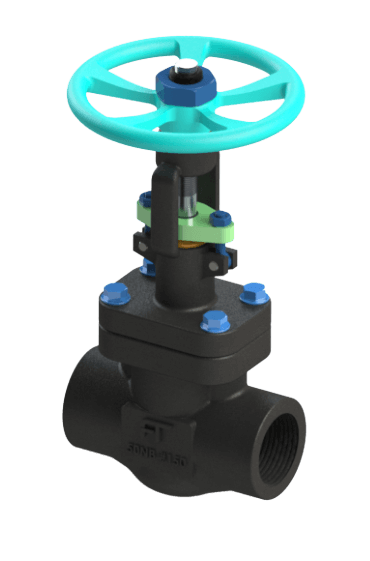

Before delving into their advantages, let's first unravel the essence of forged globe valves. These valves belong to the family of linear motion valves and are renowned for their spherical body shape with a disc that moves perpendicular to the flow to regulate fluid passage. What sets forged globe valves apart is their manufacturing process, which involves shaping metal under immense pressure, resulting in a denser and more durable material compared to cast counterparts.

|

| API 602/623 Forged Steel Globe Valve |

Unmatched Strength and Durability

One of the primary advantages of forged globe valves lies in their superior strength and durability. Crafted from high-quality materials such as stainless steel, carbon steel, or alloy steel, forged globe valves exhibit exceptional resistance to corrosion, erosion, and high temperatures. This resilience makes them ideal for handling aggressive fluids, abrasive media, and demanding operating conditions commonly encountered in industrial environments.

Precise Flow Control

Precision is paramount in industrial operations, and forged globe valves excel in providing accurate flow control. Their design facilitates fine adjustments to fluid flow, allowing operators to regulate the rate and direction of flow with precision. Whether it's throttling, isolating, or diverting flow, forged globe valves offer unparalleled control, ensuring optimal performance and efficiency across diverse applications.

Versatility Across Industries

The versatility of forged globe valves is another noteworthy advantage that resonates across various industries. From oil and gas to chemical processing, power generation, and water treatment, these valves find applications in a multitude of sectors. Their adaptability to different pressure ratings, temperature ranges, and fluid types makes them indispensable components in pipelines, refineries, petrochemical plants, and beyond.

Enhanced Safety and Reliability

Safety is non-negotiable in industrial settings, and forged globe valves play a pivotal role in ensuring operational integrity. Their robust construction and reliable sealing mechanisms minimize the risk of leaks, spills, and accidents, safeguarding personnel, equipment, and the environment. Moreover, their ability to withstand high pressures and extreme conditions enhances system reliability, reducing downtime and maintenance costs.

Optimal Performance in High-Pressure Environments

In applications where high-pressure conditions prevail, forged globe valves emerge as the preferred choice for their ability to withstand immense pressure without compromising performance. Their sturdy construction and tight sealing capabilities make them well-suited for critical services such as steam, gas, and hydraulic systems where pressure fluctuations are commonplace. By maintaining flow control under challenging circumstances, forged globe valves ensure uninterrupted operations and prevent costly disruptions.

Compatibility with Harsh Environments

Industrial environments can be harsh and unforgiving, subjecting equipment to extreme temperatures, abrasive substances, and corrosive chemicals. Forged globe valves are engineered to thrive in such hostile conditions, thanks to their robust materials and resilient design. Whether it's offshore platforms, chemical plants, or power stations, these valves endure the rigors of the environment, providing reliable performance year after year.

Cost-Effectiveness and Longevity

While the initial investment in forged globe valves may be higher compared to their cast counterparts, their long-term cost-effectiveness cannot be overstated. The durability and longevity of forged valves translate to extended service life, reducing the frequency of replacements and associated downtime. Additionally, their minimal maintenance requirements contribute to lower operating costs over time, making them a sound investment for businesses seeking efficiency and longevity.

Environmental Sustainability

In an era marked by growing environmental awareness, the significance of sustainable solutions cannot be overlooked. Forged globe valves align with this ethos by minimizing resource consumption and waste generation. Their durable construction reduces the need for frequent replacements, thereby decreasing material consumption and minimizing the environmental footprint associated with valve manufacturing and disposal.

Conclusion

In the tapestry of industrial operations, Forged Steel Globe valves emerge as indispensable components that elevate efficiency, reliability, and safety. With their unmatched strength, precise flow control, and versatility across industries, these valves embody the epitome of engineering excellence. By investing in forged globe valves, businesses not only enhance their operational performance but also embrace sustainability and resilience in an ever-evolving landscape of industrial innovation.

No comments:

Post a Comment