In the realm of industrial valves, two common types stand out: forged globe valves and cast globe valves. Both serve vital roles in controlling the flow of fluids within pipelines and systems, yet they differ significantly in their construction, materials, and performance characteristics. When it comes to deciding between the two, understanding their respective strengths and weaknesses is crucial. So, let's embark on a journey to explore the nuances of forged and cast globe valves to determine which might be the superior choice for your specific application.

The Basics: What Are Forged and Cast Globe Valves?

Before delving into the comparison, let's establish a fundamental understanding of forged and cast globe valves.

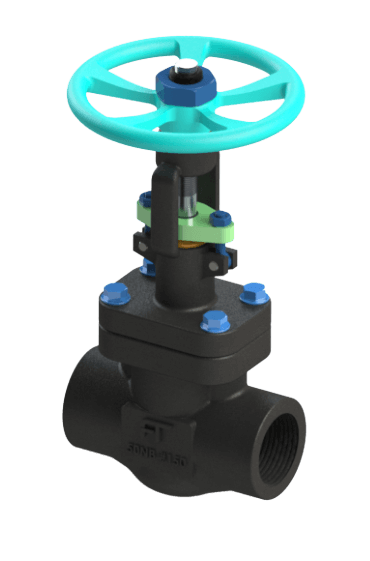

Forged Globe Valves: These valves are crafted through a forging process, where metal is shaped and formed under high pressure and temperature. This method results in valves with superior strength, durability, and resistance to pressure and temperature extremes. Forged globe valves are renowned for their robustness and reliability, making them well-suited for demanding industrial environments.

Cast Globe Valves: In contrast, cast globe valves are manufactured by pouring molten metal into molds and allowing it to solidify. While casting allows for intricate shapes and designs, cast globe valves typically exhibit lower strength and durability compared to their forged counterparts. However, they are often more cost-effective to produce and are suitable for less demanding applications.

|

| Forged Steel Globe Valve For High Temprature |

Material Composition: Strength vs. Cost

One of the primary distinctions between forged and cast globe valves lies in their material composition.

Forged Globe Valves: These valves are typically crafted from high-quality forged materials such as stainless steel, carbon steel, or alloy steel. The forging process aligns the grain structure of the metal, enhancing its strength and resistance to fatigue, corrosion, and erosion. As a result, forged globe valves are preferred for high-pressure, high-temperature applications where reliability is paramount.

Cast Globe Valves: Cast globe valves are commonly made from cast iron, cast steel, or ductile iron. While these materials offer adequate performance in moderate-pressure environments, they may lack the strength and resilience required for more demanding conditions. Additionally, the casting process can introduce impurities and inconsistencies, potentially compromising the integrity of the valve.

Performance Characteristics: Reliability under Pressure

When it comes to performance, forged and cast globe valves exhibit distinct traits that can influence their suitability for specific applications.

Forged Globe Valves: Thanks to their robust construction and superior material properties, forged globe valves excel in high-pressure, high-temperature applications. They boast excellent sealing capabilities, minimal leakage, and reliable operation even in harsh operating conditions. Additionally, forged valves are less prone to deformation or failure under extreme pressure, ensuring long-term performance and safety.

Cast Globe Valves: While cast globe valves are suitable for lower-pressure applications, they may struggle to maintain integrity under high pressures or fluctuating temperatures. Their casting imperfections and lower material strength can lead to issues such as leakage, deformation, or premature failure. As such, cast globe valves are best suited for environments where pressure and temperature requirements are less stringent.

Cost Considerations: Balancing Budget and Performance

When evaluating valve options, cost inevitably becomes a crucial factor in the decision-making process.

Forged Globe Valves: While forged globe valves often command a higher initial cost compared to cast valves, their superior durability and reliability can result in lower lifecycle costs over time. The investment in a forged valve pays dividends in terms of reduced maintenance, downtime, and replacement expenses, making it a cost-effective choice for critical applications where performance is paramount.

Cast Globe Valves: Cast globe valves are generally more budget-friendly upfront, making them an attractive option for projects with tight cost constraints. However, it's essential to weigh the long-term implications, as lower-priced valves may incur higher maintenance and replacement costs down the line. For applications where performance requirements are less stringent, cast globe valves can offer a reasonable balance between cost and functionality.

Conclusion: The Right Valve for the Job

In the debate between forged and cast globe valves, there's no one-size-fits-all answer. The optimal choice depends on a myriad of factors, including the specific application requirements, operating conditions, budget constraints, and performance expectations.

For critical applications demanding uncompromising reliability, such as petrochemical plants, power generation facilities, or offshore drilling operations, API 602 Forged Steel globe valves emerge as the clear frontrunner. Their exceptional strength, durability, and resistance to extreme conditions make them the preferred choice for safeguarding critical processes and equipment.

However, for less demanding applications where cost plays a significant role and performance requirements are moderate, cast globe valves can offer a cost-effective solution without sacrificing basic functionality.

Ultimately, the key lies in conducting a thorough assessment of your project needs and selecting the valve type that best aligns with your priorities, whether it's maximizing performance, minimizing costs, or striking a balance between the two. With careful consideration and informed decision-making, you can ensure the optimal selection of globe valves to keep your operations running smoothly and efficiently.

No comments:

Post a Comment