In the intricate network of industrial processes, efficient flow control is paramount. Whether it's regulating the flow of liquids, gases, or steam, the reliability and precision of control valves are essential for smooth operations. Among the array of valve types available, forged globe valves stand out for their robustness, versatility, and ability to optimize flow control in various applications. In this article, we delve into the world of forged globe valves, exploring their construction, functionality, advantages, and applications, and how they contribute to enhancing efficiency in industrial settings.

Understanding Forged Globe Valves:

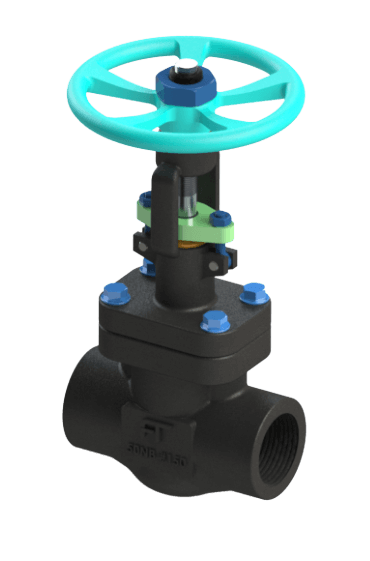

Forged globe valves are a type of control valve widely used in industries where precise regulation of fluid flow is crucial. Unlike their counterparts, such as gate valves or ball valves, forged globe valves are designed with a globe-shaped body and a movable disk or plug that regulates the flow through the valve. This unique design allows for fine-tuning of flow rates, making them ideal for applications requiring accurate control over flow parameters.

|

| API 602 Forged Globe Valve Supplier in India |

Construction and Functionality:

The construction of forged globe valves typically involves high-quality forged materials such as stainless steel, carbon steel, or alloy steel. This forging process ensures superior strength, durability, and resistance to corrosion, making them suitable for demanding industrial environments. The valve body is usually designed to withstand high pressures and temperatures, with options for various end connections to facilitate installation in different piping systems.

At the heart of the forged globe valve lies the valve trim, which consists of the valve disk, stem, and seating arrangement. The disk, also known as the plug, moves perpendicular to the flow direction to modulate the flow through the valve. This linear motion of the disk allows for precise control over the flow rate, making forged globe valves ideal for throttling applications where flow regulation is critical.

Advantages of Forged Globe Valves:

Forged globe valves offer several advantages over other types of valves, making them a preferred choice in many industrial applications. One significant advantage is their excellent throttling capability, which allows for precise control over flow rates, pressure drops, and fluid levels. This precision is essential in processes where even minor deviations can impact product quality or system performance.

Furthermore, forged globe valves exhibit minimal pressure drop across the valve, ensuring efficient flow control without significant energy losses. This feature not only enhances system efficiency but also reduces operational costs over the long term. Additionally, the robust construction of forged globe valves enhances their reliability and longevity, resulting in reduced downtime and maintenance requirements.

Applications of Forged Globe Valves:

The versatility of forged globe valves makes them suitable for a wide range of industrial applications across various sectors. In the oil and gas industry, forged globe valves are used in upstream, midstream, and downstream processes, including wellhead control, pipeline transportation, and refining operations. Their ability to handle high pressures and temperatures makes them ideal for critical service applications where safety and reliability are paramount.

Moreover, forged globe valves find extensive use in power generation plants, chemical processing facilities, petrochemical refineries, and HVAC systems, among others. In these applications, they play a crucial role in regulating fluid flow, controlling process parameters, and maintaining system efficiency. Whether it's controlling steam flow in a boiler system or regulating chemical feed in a production process, forged globe valves provide the precision and reliability required for optimal performance.

Conclusion:

In the quest for efficiency and productivity, forged globe valves emerge as indispensable components in industrial flow control systems. Their robust construction, precise throttling capability, and versatile applications make them a preferred choice for engineers and operators striving to optimize process performance. By understanding the construction, functionality, advantages, and applications of forged globe valves, industries can harness their potential to enhance efficiency, improve reliability, and achieve operational excellence in their processes. As technology advances and industrial demands evolve, forged globe valves will continue to play a vital role in shaping the future of flow control across various sectors. Freture Techno is leading High Pressure Forged Steel Globe Valve Manufacturer in Mumbai, India. Get in touch with us to know more about products.

No comments:

Post a Comment