PTFE (Polytetrafluoroethylene) lined gate valves have emerged as essential components in various industries, particularly where corrosive and aggressive fluids are handled. These valves are designed to provide superior chemical resistance, ensuring the integrity of the system while minimizing the risk of leakage and failure. As industries seek reliable solutions for fluid control, the role of PTFE lined gate valves becomes increasingly significant.

What are PTFE Lined Gate Valves?

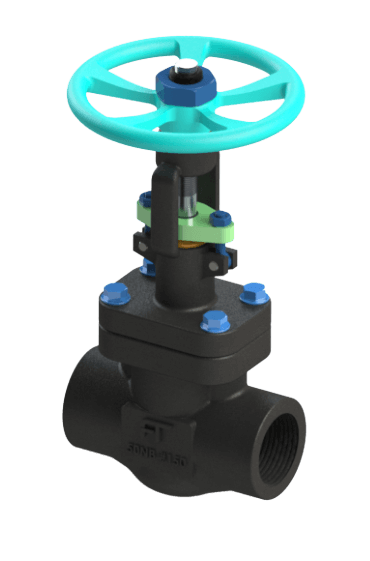

They are designed with a metal body that is coated internally with PTFE, a non-stick and chemically resistant material. This lining offers a barrier that protects the valve body from the corrosive effects of harsh chemicals, extending the lifespan of the valve and reducing maintenance costs. The gate valve design facilitates a straight flow path, minimizing pressure loss and allowing for efficient operation in fluid systems.

|

| PTFE Lined Gate Valves Manufacturers in India |

Key Features and Advantages

Chemical Resistance: The primary advantage of these valves lies in their exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. This characteristic makes them suitable for industries such as chemical processing, pharmaceuticals, and petrochemicals, where fluid composition may vary significantly.

Reduced Friction: The smooth surface of PTFE reduces friction, enabling easier operation of the valve. This is particularly beneficial in applications requiring frequent valve actuation, as it enhances the overall efficiency of the system.

Temperature Tolerance: PTFE can withstand a broad temperature range, making these valves applicable in various thermal conditions. This thermal stability ensures reliable performance even in extreme environments.

Leak Prevention: The design of these valves helps in preventing leaks. The lining effectively seals the valve, which is crucial for maintaining safety in operations involving hazardous materials.

Longevity and Durability: The protective PTFE lining significantly increases the lifespan of the valve. This durability translates into lower replacement costs and less downtime, providing an economical solution for industrial processes.

Applications in Various Industries

They are widely utilized across multiple sectors due to their unique properties. Some common applications include:

Chemical Processing: In chemical plants, where corrosive substances are frequently handled, these valves are critical in maintaining safety and efficiency. The ability to resist chemical attacks ensures that operational integrity is upheld.

Pharmaceutical Industry: The pharmaceutical sector requires strict adherence to hygiene and safety standards. They are often employed in water treatment systems and in the transport of raw materials, ensuring that contaminants do not compromise product quality.

Oil and Gas: In the oil and gas industry, where fluids can be both corrosive and abrasive, They are indispensable. They facilitate safe and efficient fluid flow, meeting the rigorous demands of this sector.

Food Processing: The food and beverage industry also benefits from these valves, as their non-toxic nature and ease of cleaning make them suitable for applications where hygiene is paramount.

Selection Criteria for PTFE Lined Gate Valves

When selecting valves, several factors should be considered to ensure optimal performance:

Pressure Rating: The pressure rating of the valve must match the requirements of the system. This specification ensures that the valve can handle the operating conditions without failure.

Size: The size of the valve should be determined based on the pipe diameter and the flow requirements of the system. Proper sizing is crucial to ensure effective fluid control.

End Connections: The type of end connections, whether flanged, threaded, or welded, should align with the existing piping systems to facilitate seamless installation.

Temperature Range: It is essential to evaluate the operating temperature to select a valve that will perform reliably under those conditions.

Standards and Certifications: Compliance with industry standards and certifications should be verified to ensure that the selected valve meets all necessary safety and quality requirements.

Conclusion

They represent a crucial advancement in valve technology, providing unmatched protection against corrosion and leakage in fluid handling systems. Their applications span various industries, underscoring their versatility and reliability. When selecting these valves, it is vital to consider the specific operational requirements to maximize performance.

For businesses seeking high-quality solutions, PTFE Lined Gate Valve Manufacturers offer a range of products designed to meet stringent industrial standards.

Buy PTFE Lined Gate Valve from Freture Techno Pvt. Ltd., a leading manufacturer committed to delivering innovative and reliable valve solutions tailored to the needs of diverse industries.