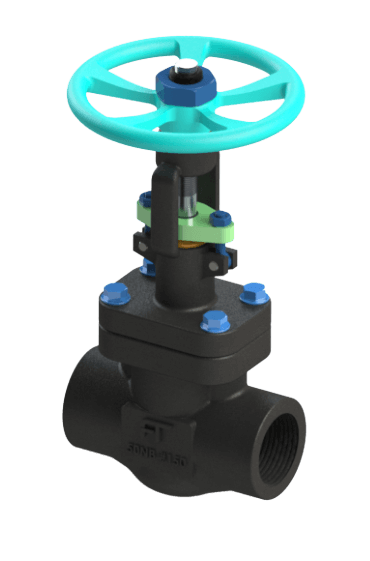

Forged globe valves are specifically designed for high-pressure applications, where safety, durability, and precision are critical. These valves are widely used in industries where the flow of liquids or gases must be controlled under challenging conditions. This article delves into why forged globe valves are indispensable for high-pressure applications and what factors to consider when choosing the right valve.

Why Use Forged Steel Globe Valves for High-Pressure Applications?

The forging process used in manufacturing these valves gives them an edge in high-pressure environments. Unlike cast globe valves, which are prone to cracks and weaknesses due to casting imperfections, forged globe valves are made from a single piece of metal that is compressed under extreme force. This results in:

- Increased Tensile Strength: They are better able to withstand the mechanical stresses associated with high-pressure operations.

- Enhanced Impact Resistance: With the absence of internal flaws, the risk of failure under sudden pressure changes is minimized.

- Improved Temperature Handling: Suitable for applications involving both extremely high and low temperatures.

|

| Forged Steel Globe Valve Manufacturers in Mumbai, India | Freture Techno |

Factors to Consider When Selecting Forged Globe Valves

When choosing forged globe valves for high-pressure applications, consider the following aspects:

- Pressure Rating: Ensure the valve can handle the specific pressure requirements of your system. Look for valves with pressure ratings up to 4500 PSI for demanding applications.

- Material Selection: The choice of materials, such as stainless steel or alloy steel, depends on the media being controlled. Corrosive fluids may require corrosion-resistant alloys.

- Valve Size and Connection Type: Selecting the appropriate size and end connection (flanged, threaded, or socket-weld) will ensure compatibility with the pipeline.

Common Uses of Forged Globe Valves in High-Pressure Scenarios

- Oil Refining: Manages the flow of crude oil and other hydrocarbons under high pressures.

- Power Plants: Used in boiler feedwater systems and steam control for turbines.

- Mining Operations: Controls the flow of slurry and other high-pressure fluids.

Forged globe valves offer unmatched reliability and performance in high-pressure applications. Freture Techno robust construction and ability to withstand intense conditions make them a preferred choice in industries where safety and durability are non-negotiable. Choosing the right Forged Steel Globe valve involves understanding the specific requirements of your system, including pressure, temperature, and material compatibility.

No comments:

Post a Comment