In the realm of fluid control within industrial systems, the globe valve stands as a pivotal player, offering precise control and regulation of liquid and gas flow. This versatile valve design has been a cornerstone of various industries for decades, proving its reliability and efficiency. In this in-depth article, we explore the intricacies of globe valves, covering their design, types, applications, advantages, and crucial considerations for optimal utilization.

Understanding Globe Valves: The Core Principles

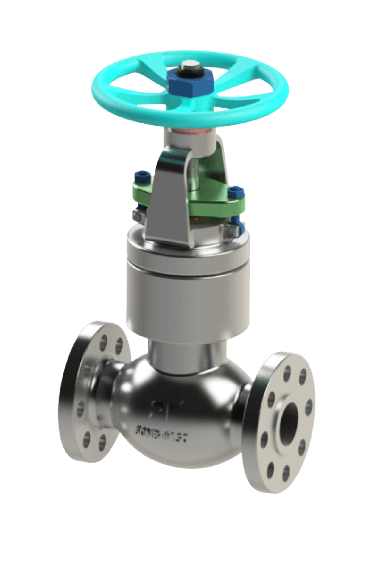

A globe valve is a linear motion valve that controls the flow of fluid by moving a disc up and down on a spindle within the valve body. This movement modulates the flow rate and allows for precise control over the fluid passing through the valve.

Anatomy of a Globe Valve

Valve Body: The main casing of the valve, housing all the internal components.

Disc (Plug): The disc is connected to the spindle and controls the flow through the valve. When the valve is open, the disc is lifted, allowing fluid to pass. When closed, the disc is lowered, blocking the flow.

Spindle (Stem): The spindle connects the actuator (handle, wheel, or motor) to the disc. Rotating the actuator raises or lowers the disc, controlling the flow.

Seat: The seat provides a sealing surface for the disc, preventing leakage when the valve is closed.

|

| Types of Globe Valves |

Types of Globe Valves

1. Tee Pattern Globe Valve:

In this design, the valve body and ports are at right angles to each other. This configuration provides a more compact design and is commonly used in applications with limited space.

2. Y-Pattern Globe Valve:

The Y-pattern globe valve has a body with a Y-shaped configuration, offering a streamlined flow path and reduced pressure drop. It's preferred for applications requiring minimal turbulence and pressure loss.

3. Angle Pattern Globe Valve:

The angle pattern globe valve has the inlet and outlet ports at an angle, making it suitable for applications where the flow path needs redirection or a change in direction.

|

| Pressure Seal Globe Valve Manufacturer in Mumbai, India |

Common Applications of Globe Valves

1. Boiler Systems:

Globe valves are crucial components in boiler systems, regulating the flow of steam and water to maintain desired pressure levels.

2. Heating, Ventilation, and Air Conditioning (HVAC) Systems:

Globe valves control the flow of hot or cold water in HVAC systems, aiding in temperature regulation.

3. Steam and Process Piping:

In industrial settings, globe valves manage the flow of steam and other fluids within process piping.

4. Shipbuilding and Marine Industry:

Globe valves are extensively used in ship systems to control the flow of water, fuel, and other fluids necessary for marine operations.

Advantages of Globe Valves

Precise Flow Control:

Globe valves offer accurate control over flow rates, making them ideal for applications where precise regulation is crucial.

Good Shut-Off Capability:

Globe valves provide an effective seal when closed, preventing leakage and ensuring a tight shut-off.

Versatility in Pressure and Temperature:

Globe valves are suitable for a wide range of pressures and temperatures, making them adaptable to diverse applications.

Durable and Long-Lasting:

Properly maintained globe valves can have a long service life due to their sturdy construction and simple design.

Key Considerations When Using Globe Valves

Material Selection:

Choose appropriate materials for the valve body, disc, and seat based on the type of fluid, pressure, and temperature to ensure compatibility and longevity.

Actuation:

Consider the method of actuation (manual, pneumatic, electric) based on the application's requirements for control and automation.

Proper Sizing:

Size the valve appropriately for the required flow rate to ensure optimal performance and prevent issues like cavitation and excessive pressure drops.

Maintenance and Lubrication:

Regular maintenance and proper lubrication of moving parts are crucial to ensure smooth operation and extend the valve's service life.

In the dynamic landscape of valve manufacturing, Freture Techno Pvt. Ltd stands out as a distinguished Global valve manufacturer in Mumbai, India. With a rich legacy of engineering excellence and a commitment to delivering superior-quality valves, Freture Techno has firmly established itself as a reliable partner for industries worldwide. Their globe valves, crafted with precision and designed for optimal performance, embody innovation and adhere to international standards. By blending state-of-the-art technology with a customer-centric approach, Freture Techno continues to set new benchmarks, offering a comprehensive range of valves that cater to diverse industrial needs. With a focus on quality, innovation, and customer satisfaction, Freture Techno Pvt. Ltd continues to stride confidently towards shaping the future of fluid control systems.

No comments:

Post a Comment