Exploring the Efficiency and Reliability of Pressure Seal Globe Valves

In the vast landscape of fluid control systems, pressure seal globe valves stand out as essential components, playing a crucial role in controlling the flow of liquids and gases under high pressure and temperature conditions. Their robust design and efficiency make them vital for various industrial applications. In this in-depth article, we'll unravel the intricacies of pressure seal globe valves, exploring their design, advantages, applications, and important considerations for optimal utilization.

Understanding Pressure Seal Globe Valves: A Comprehensive Overview

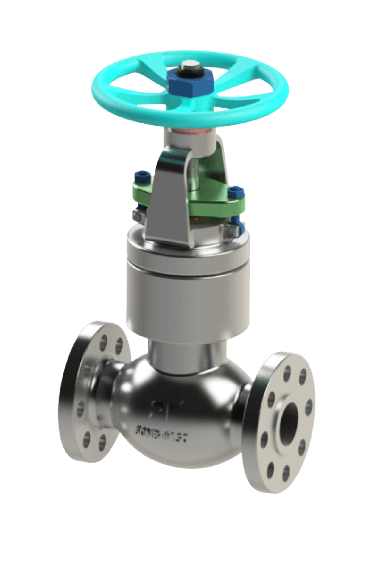

Pressure seal globe valves are valves used to regulate the flow of fluids within a pipeline. They operate by raising or lowering a disc within the valve, controlling the flow through a central passageway. What sets pressure seal globe valves apart is their unique design, allowing them to effectively manage high pressures and temperatures, making them ideal for critical applications.

|

| Pressure Seal Globe Valve Manufacturer in Mumbai, India |

Design and Structure of Pressure Seal Globe Valves

Pressure Seal Bonnet:

The distinguishing feature of pressure seal globe valves is the pressure seal bonnet. This design ensures a tight seal at high pressures, enhancing the valve's safety and performance.

Globe-Shaped Disc:

The disc of a pressure seal globe valve is shaped like a globe, which aligns with the valve seat to control the flow. The disc movement allows for precise throttling and regulation of flow.

Stem and Actuator:

The stem, connected to the disc, moves up and down to control the opening and closing of the valve. The actuator, often a handwheel or automated mechanism, facilitates smooth operation.

Body and Seat:

The valve body contains the passageway through which the fluid flows. The seat, often made of durable materials, forms a seal with the disc to control flow.

Advantages of Pressure Seal Globe Valves

High Pressure Handling:

Pressure seal globe valves are designed to handle high-pressure applications, making them suitable for critical environments where pressure control is paramount.

Tight Seal and Leak Prevention:

The pressure seal design ensures a tight seal, minimizing the risk of leakage even under extreme pressure conditions.

Precise Flow Control:

The globe-shaped disc design allows for precise throttling and control of flow, making these valves ideal for applications requiring accurate regulation.

Versatility in Applications:

Pressure seal globe valves find applications across industries, including power generation, petrochemicals, oil and gas, where high-pressure steam and fluids need precise control.

Common Applications of Pressure Seal Globe Valves

- Power Plants:

- Pressure seal globe valves are extensively used in power plants to regulate the flow of high-pressure steam in turbines and other systems.

- Oil and Gas Industry:

- These valves are vital in the oil and gas sector, controlling the flow of crude oil, natural gas, and other hydrocarbons in high-pressure pipelines.

- Petrochemical Processing:

- Pressure seal globe valves play a key role in managing the flow of chemicals and petrochemicals in high-pressure processing environments.

- Refineries:

- In refineries, pressure seal globe valves are utilized to control the flow of various fluids at elevated pressures and temperatures.

- Key Considerations When Using Pressure Seal Globe Valves

Material Selection:

Choose materials compatible with the fluid and operating conditions to ensure longevity and reliability of the valve.

Proper Installation and Maintenance:

Follow manufacturer guidelines for installation and conduct regular maintenance to ensure optimal performance and a longer service life.

Operating Conditions:

Understand the specific operating conditions, including pressure and temperature, to select the appropriate pressure seal globe valve for the application.In the realm of fluid control solutions, Freture Techno Pvt. Ltd. stands as a distinguished leader in pressure seal globe valve manufacturing, with a strong presence in Mumbai, India. Their commitment to precision engineering, cutting-edge technology, and adherence to stringent quality standards have positioned them at the forefront of the industry. Freture Techno's pressure seal globe valves, known for their reliability, durability, and exceptional performance, cater to a vast array of critical applications across various sectors. With a customer-centric approach and a rich legacy of delivering excellence, Freture Techno Pvt. Ltd. continues to redefine and elevate the standards of fluid control technologies.